It is a rare occasion when any event effectively debunks the too-good-to-be-true principle. One such thing in the real estate sector is the significant progress made in terms of affordability, offsite construction, faster processing, better quality and considerably less off-site time. It’s truly remarkable how technology and data are reshaping the real estate industry, enabling smarter decisions and ensuring sustainability.

This is the contribution of 3D printing in real estate towards construction towards sustainability. Remember the futuristic homes of Jetsons? How they seemed to magically appear? Our world might not be too far away from that vision. Imagine being able to build complete homes in a matter of days! That is what technology can do – and it is now revolutionising the world of real estate too.

What is 3D Printing in Real Estate?

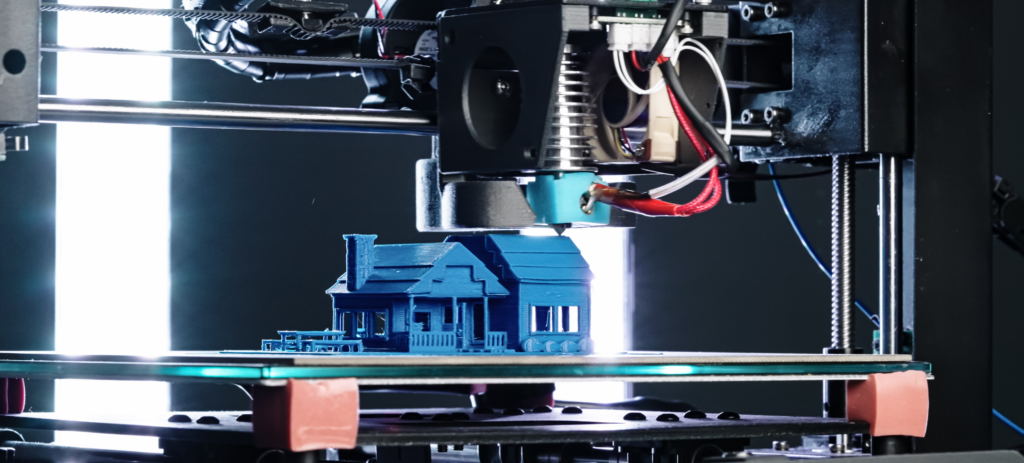

Also known as additive manufacturing, it is a fascinating yet disruptive technology that has now begun to slowly take over the thoughts and minds of many visionary leaders around the world. In simple words, it is a technology that builds objects layer by layer, transforming it into something more tangible. From plastic toys to medical equipment, 3D printing is already making its impact around various industries. And now, this technology is beginning to make its way into real estate and changing the way we envision houses, skyscrapers and community accommodation.

3D Printing in Real Estate

For architects and engineers, the magic of 3D printing begins with the very design. A blue print for the building is created using a special software. Once the design is ready, it is sent to a giant industrial sized printer, such as the Vulcan 3D printer, that goes on to build the entire design one tiny layer at a time.

With the digital footprint in place, the printer will proceed to dispense a paste like mixture which often consists of a blend of cement, special polymers, bio-resin, clay, wood flour, sawdust etc.

Crazy fact? Industrial sized 3D printers have made it possible to build entire houses in as less as 24 hours. Although, we would need to keep in mind that if the printer is meant to construct a home, the printer itself should outsize it.

What 3D Printing Can Do

- Affordable Construction

This method of construction can slash off the costs to a great extent. Traditional buildings are generally expensive – it covers the cost of labor, raw materials etc. 3D printing requires less labor and fewer materials. This can result in more affordable properties.

- Better Speed & Efficiency

In traditional construction, time is money. Delays can stretch projects out for months or even years. As mentioned before, with 3D printing in real estate, homes can be built in days, not months. The printer doesn’t sleep. It doesn’t take lunch breaks. It just works. This speed allows developers to get more work done faster, and at a fraction of the usual cost.

- Endless Possibilities

With 3D printing, buildings can now be constructed in complex, intricate designs that may not be easily possible through traditional construction. It opens the arena for architects and designers and they are no longer limited by convention.

- Much Safer than Traditional Construction.

Construction sites are generally dangerous with a large number of laborers working on the site under difficult conditions. With 3D printing, there would be fewer workers on the site and this will keep the workers out of harm’s way for the most part.

3D Printing in Real Estate Today

MYATA, Dubai

Across the world, 3D printing in real estate is no more just a concept, it has already started to take shape and is now turning into a reality.

For example, Dubai has set the bar for innovation quite high with MYATA Platinum lounge, one of the world’s largest 3D printed restaurants, located in City Walk. This architectural marvel consists of 27 canyon-like formations made from over 20,000 3D-printed components, and took 150,000 hours to complete. The lounge uses recycled plastic, enhancing its sustainability, and features textured paint finishes for a raw, organic look.

The design draws inspiration from the natural rock formations of the Emirates, creating a serene, immersive atmosphere with curved structures and funnel-shaped entrances. The space offers a relaxing escape with outdoor terraces and lush greenery.

MYATA Platinum Lounge also aligns with Dubai’s 3D Printing Strategy 2030, aiming to have 25% of the city’s buildings constructed using 3D printing. It contributes to the UAE’s goal of reducing carbon emissions by 8.8 million tonnes annually, making this project not only an architectural achievement but also a step towards a sustainable future. The lounge is currently undergoing a verification process to secure a Guinness World Record.

EMAAR

Emaar, one of the world’s leading real estate developers, has unveiled Dubai’s first-ever 3D-printed house in the Arabian Ranches III area. This ground-breaking project highlights Emaar’s commitment to innovation, quality, and sustainability. The 202 m² (2,175 SF) villa, designed by U+A Architects, features curved walls, large windows, and integrates advanced technologies like Xiaomi’s Mobile X AIOT products, offering a glimpse into the future of smart living.

This pioneering initiative is part of Dubai’s ‘Smart City’ vision, aligning with the goal of having 25% of all construction projects 3D printed by 2030. Emaar’s use of 3D printing technology aims to build homes faster, more cost-effectively, with unique designs, and with less waste and noise pollution. The project also marks a significant step in redefining construction norms and advancing sustainable building practices.

Limitations of 3D Printing in the Current World

For example, with the coming of 3D printing in real estate, developers and professionals must consider several challenges and drawbacks, for example:

- Material Limitations

3D printing, though advanced with regards to the usage of materials, it still primarily relies on a limited selection of substances, such as plastic, metal, and certain types of concrete. The diversity of printable materials is still somewhat restricted, which can limit the variety of products or buildings that can be created, especially in fields like real estate or manufacturing.

- High Costs

Though effective, it cannot be argued that the gigantic printers do come at a staggering price. This includes the cost of the printer itself, as well as maintenance, skilled labor, and materials. While the technology can reduce long-term costs, the initial investment can be a significant barrier for many companies, especially smaller enterprises.

- Quality & Durability

While there is absolutely no doubt that the result of a 3D printed building comes with high precision, it is still in its early stage. Due to this, there are several concerns about its durability. There are some critical thinkers who believe that the buildings may not hold their structure, but studies are currently on going about their structural integrity.

- Impact on the Environment

Although 3D printing is considered sustainable due to the use of limited materials, the printer itself is quite energy-intensive. The production of 3D printers, especially large ones used in construction or manufacturing, requires significant energy, and their use can contribute to carbon emissions, especially if powered by non-renewable energy sources.

- Potential unemployment

As 3D printing becomes more integrated into industries like construction, it could reduce the need for manual labor. While new jobs in design, machine operation, and maintenance could arise, automation may lead to job losses in traditional roles.

Conclusion

Even so, the future of 3D printing in construction is bright. This technology can make homes affordable and accessible to millions around the world. It opens up endless possibilities for real estate developers who are ready to embrace the changes in this rapidly evolving industry. A true game-changer, 3D printing solves many problems that traditional construction cannot.

As innovation continues to unfold, 3D printing promises a broad spectrum of future innovations within the industry. Developers who grasp this technology today can lead the charge tomorrow, positioning themselves as forward-thinking professionals in the industry. The opportunity is here. Will you step forward and seize it?

Apr 19, 2022

Apr 19, 2022

12:00:39am

12:00:39am